Fresh Hummus and Salsa Using Hiperbaric Technology

Ithaca Hummus is one of the leading premium hummus brands in America. Their hummus is known for its quality taste, freshness, and the use of premium-quality ingredients. Ithaca Hummus relies on High-Pressure Processing, also known as HPP, to keep the ingredients fresh and full of nutrients, while also extending their shelf-life from 28 days to more than 100. With this extended shelf-life, Ithaca has been able to scale its products nationwide in over 8,200 stores, including premium, natural and conventional retailers such as Wegmans, Whole Foods, Publix, Sprouts, Stop and Shop, Hannaford, Safeway, Albertson’s and more. Ithaca is now sold in every state so everyone can taste hummus for the first time, even if it’s your hundredth time.

Ithaca Farmers Market – Where It All Began

Ithaca Hummus is a New York-based company founded by Chris Kirby who wanted to create a product he would enjoy eating. This led him to sell hummus at the Ithaca Farmer’s Market in 2013.

Chris, who still runs the company today, said he showed up to that farmer’s market, “with a cooler of fresh lemon garlic hummus and a dream.” He also brought with him experience working as a restaurant chef and a lifelong dedication to real, wholesome food.

Over the years, that dream has become a reality. Ithaca Hummus is now one of the leading premium hummus brands in America and has developed a cult-like following of loyal fans who love them for the restaurant's quality taste and texture of their hummus.

Fresh-squeezed lemon juice was an important ingredient in the first batch of hummus Chris made, and it continues to be a major aspect of many of Ithaca Hummus’s appealing and slightly tangy flavors today.

In the beginning, they would hand-squeeze fresh lemon into every batch. The hummus was blended and packaged the night before it was sold at the farmer’s market.

Chris states, “We’re incredibly proud of the fact that ten years later we’re still squeezing fresh lemons. The only thing that’s changed is I’m no longer personally doing it myself, by hand. I joke sometimes and say that we’re the only brand with a cold-pressed juicery inside our manufacturing plant.”

Hummus, Cold-Crafted for Freshness

Much of the food in grocery stores is processed with heat pasteurization, industrial ingredients, and preservatives. At Ithaca, they’re changing that and making it easier for people to eat real food, made from real food, that tastes the same as what you’d expect from a restaurant.

When you heat fresh ingredients, they don’t taste fresh anymore. Most brands blend their hummus while the chickpeas are still hot because it’s faster, cheaper, and easier. At Ithaca, they cool the chickpeas and blend their hummus cold to keep the ingredients fresh. This unique process helps maintain the integrity of their ingredients.

Ithaca uses all real ingredients in its products, such as chickpeas, cold-pressed lemon juice, tahini (sesame seed paste), raw garlic, cumin, and salt.

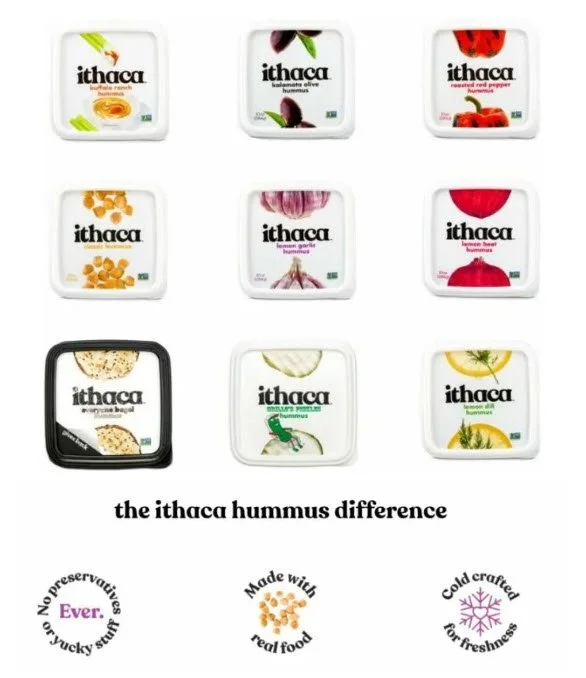

Ithaca goes as far as cold-pressing their lemon juice on-site prior to blending their hummus. The company’s products do not contain preservatives or additives like sugar or artificial colors. This approach has led them to define “the Ithaca Hummus difference” – which means no preservatives or yucky stuff, using real food and a cold-crafted approach for freshness.

Chris Kirby states, “The reason our hummus tastes so fresh is that we use fresh ingredients like cold-pressed lemon juice and fresh raw garlic. If you heat these ingredients, they won’t taste fresh anymore! So, unlike most brands who blend their hummus while the chickpeas are still hot, we cool the chickpeas and blend our hummus cold to keep the ingredients fresh. ”

Partnership Drives Growth: Ithaca, LiDestri Foods & Hiperbaric HPP Technology

Ithaca has come a long way from the Ithaca Farmer’s market days and has experienced rapid growth, dipping into a billion-dollar industry.

The growth coincides with a business partnership between Ithaca, LiDestri Foods, and Hiperbaric. That partnership was forged in 2016 and moved the business from Ithaca to Rochester. LiDestri Foods serves as a co-manufacturer and HPP tolling provider and Hiperbaric is the manufacturer and supplier of HPP equipment.

“Right now, we’re producing around 150,000 pounds of hummus a week,” Frank Cavallaro, COO, said, adding they have the capacity to double that number. “When we started out with LiDestri, we were closer to about 13,000 pounds a week. In 2017, we didn’t even break $1 million in sales. But this year, we’re going to probably surpass about $25 million.”

Until recently, Ithaca Hummus still was cooking the chickpeas in a handful of small tanks, then cooling the batches in a refrigerator and blending. The whole process took about 24 hours. They decided to invest in a specially designed, automated cooking process using dried beans. That system was operational in August and completes the process in just two hours.

The new processing line effectively eliminates supply chain concerns and saves money.

Ithaca Hummus also relies on high-pressure processing equipment through LiDestri Foods using a Hiperbaric 525. This allows them to not rely on preservatives or a high-temperature “kill” process to eliminate or slow bacteria growth and extend shelf life. HPP extends the shelf life of their hummus from 28 days to more than 100.

With this extended shelf-life, Ithaca has been able to scale its products nationwide in over 8,200 stores, including premium, natural and conventional retailers such as Wegman’s, Whole Foods, Publix, Sprouts, Stop and Shop, Hannaford, Safeway, Albertson’s and more. Ithaca is now sold in every state, continues to add stores, and is looking to break into club stores.

Spicy Future with Ithaca Salsa

Salsa is another category where you rarely find restaurant quality, homemade taste and texture in a store-bought brand. Ithaca has made it a priority to change that.

Just like their hummus, fans are already raving about the “wow-factor” fresh taste and texture of their salsa, and they’re loving the depth of flavor they’ve added by fire roasting the tomatoes.

Ithaca recently launched their new Fire Roasted Salsas collection featuring a trio of fresh salsas with a smoky punch, available in Mild, Medium, and Hot on the horizon, looking to meet the demand for a less processed option using HPP.

In the words of Chris, “We have no plans on stopping. We still have that scrappy mentality that we had when we started out at the Ithaca Farmer’s Market. We’re food lovers first, and business people second, so we’re always pushing limits. Build a cold-pressed juicery inside a food manufacturing plant? Why not? Making the impossible possible can only occur when you’re crazy enough to imagine it.”

Original Article by Hiperbaric, please visit https://www.hiperbaric.com/ or contact ITD for more information.