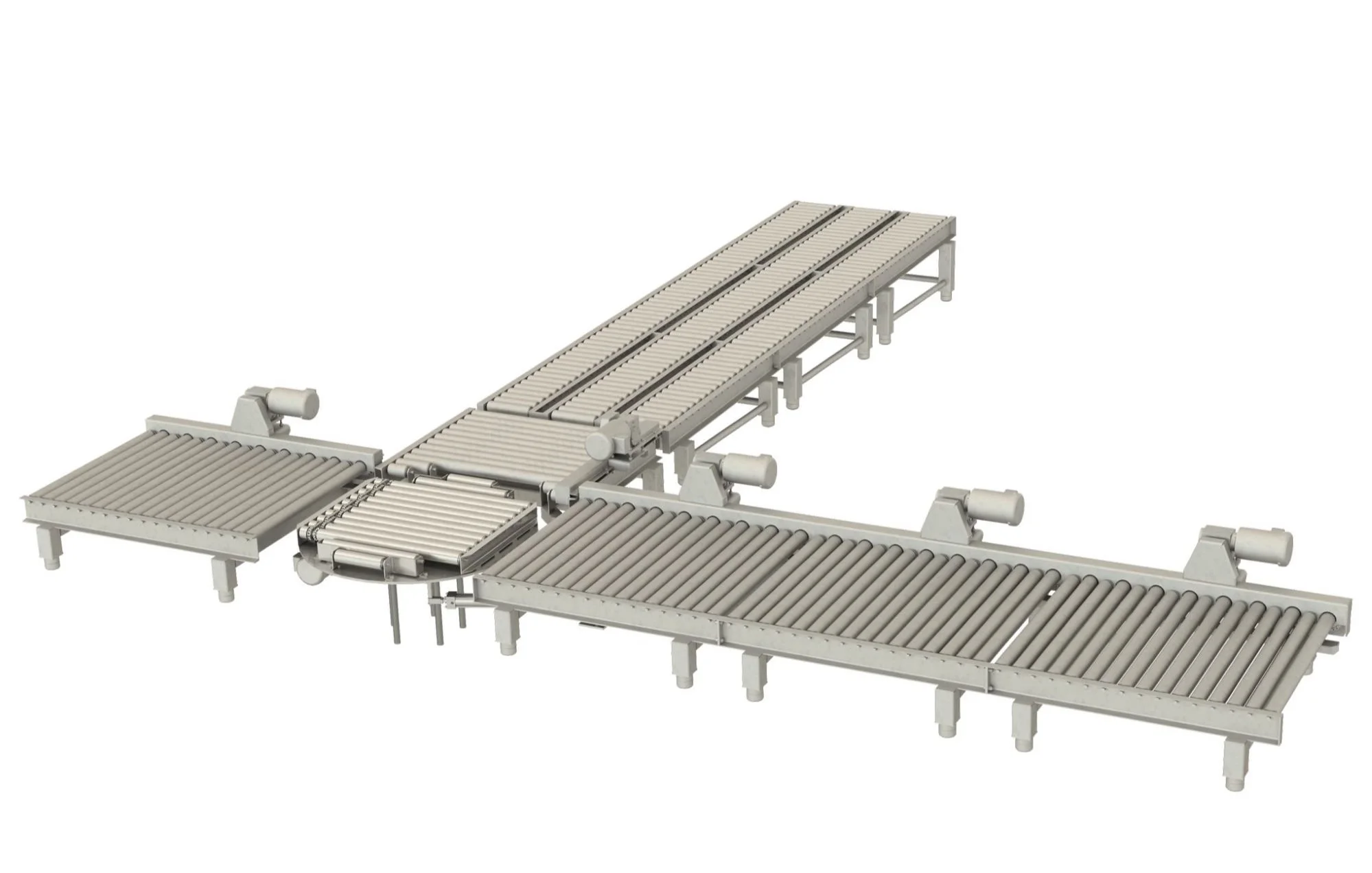

Introducing Challenge RMF’s New Line of Pallet Conveyors

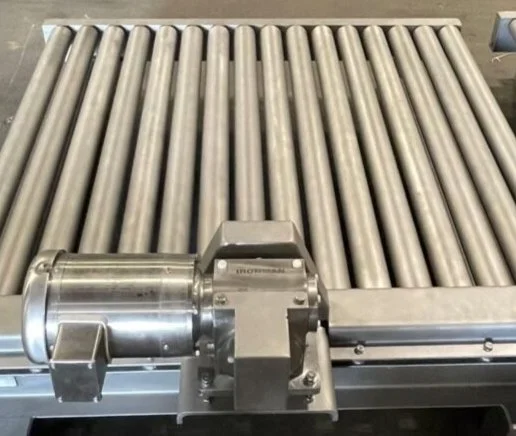

RMF Pallet Conveyors offer unparalleled customization options, allowing customers to tailor the conveyor system to fit their unique production requirements. These conveyors utilize a series of heavy-duty cylindrical rollers, which create smooth, continuous surface for transporting materials and products within a production facility.

Versatility

Conveying systems in production facilities are not always compatible with a linear design. Additionally, complex systems will require conveyors to handle more then one type of product at a time. It is often crucial to have a conveying system that can pivot, change directions within a facility, and handle different products simultaneously. RMF Pallet Turntables enable complex conveyor line designs/layouts to maintain efficiency. They also facilitate the sorting of multiple types of products onto different conveyor lines, without requiring additional physical labor.

Reliability

RMF Pallet Conveyors are designed and constructed to withstand the rigors of industrial environments. We make them with high-quality materials, precision engineering, and meticulous craftsmanship to guarantee reliable performance. These conveyors can handle heavy loads, withstand continuous operation, and overcome challenges posed by various manufacturing processes, thanks to their structural integrity.

Safety and Enhanced Efficiency

By eliminating the need for manual handling and physical labor, RMF Pallet Conveyors actively reduce the risk of injuries, increase operational safety, and enhance employee satisfaction. They actively contribute to enhanced operational efficiency by reducing handling time and streamlining pallet flow.

Original Article by Challenge RMF, please visit https://rmfworks.com/ or contact ITD for more information.